Why do builders prefer custom aluminum extrusions?

- Enable design flexibility

- Deliver a high strength-to-weight ratio

- Ensure durability and corrosion resistance

- Support sustainability and energy efficiency

- Improve cost efficiency

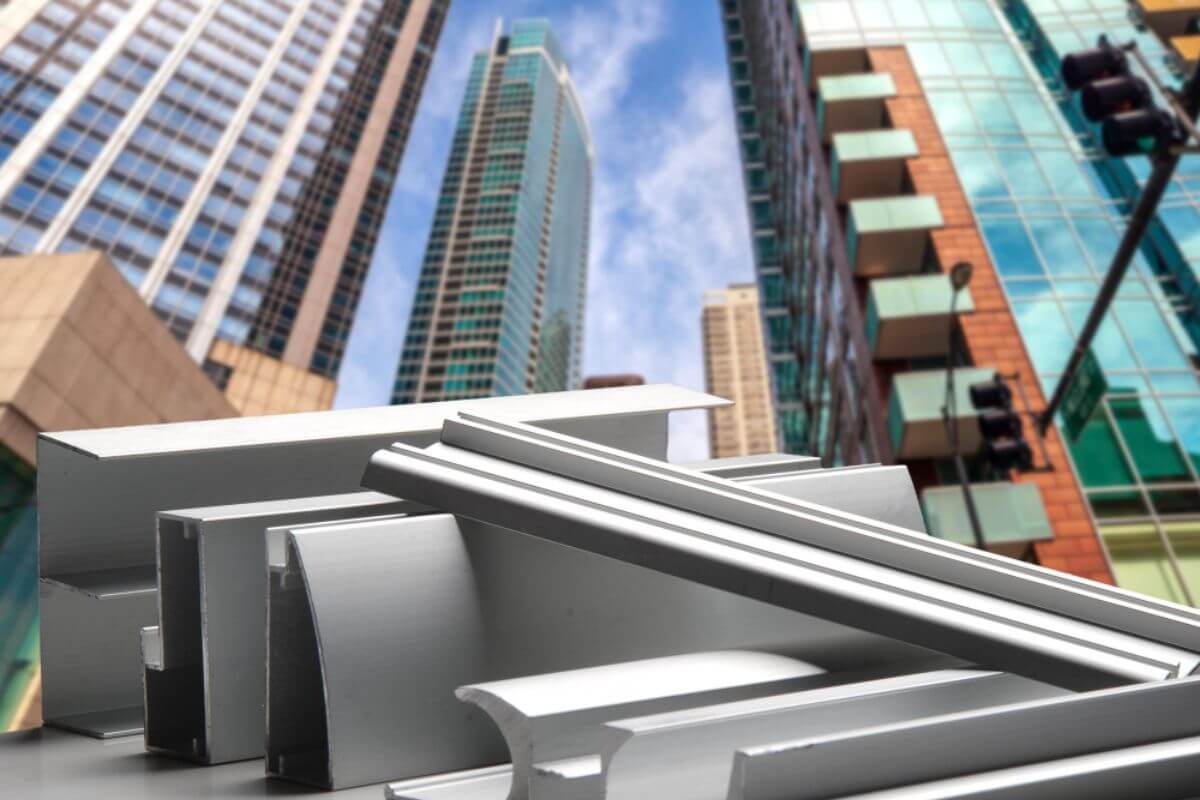

Overview

- Custom aluminum extrusions offer flexibility, optimized strength-to-weight ratios, and enhanced durability for complex projects.

- They reduce fabrication, installation, and maintenance costs while supporting sustainability and energy efficiency.

- Tailored to specific design and performance requirements, they outperform standard profiles, making them ideal for architectural applications, high-performance structures, and energy-conscious builds.

Choosing between custom aluminum extrusions and standard profiles depends on project fit, performance, and execution efficiency. Standard profiles suit many builds, but complex or non-standard conditions often require custom solutions. Custom extrusions offer flexibility, but they should prioritize functional requirements over purely aesthetic preferences.

In this article, we’ll explore why builders prefer custom aluminum extrusions over standard profiles and highlight the factors to consider when determining which option makes the most sense for your project.

Enable Design Flexibility

Greater design flexibility becomes possible when profiles are shaped around specific openings, hardware, and performance requirements rather than fixed standard dimensions. As a result, you gain more control over both appearance and functionality from the outset.

Custom extrusions offer flexibility that standard profiles cannot, accommodating non-standard dimensions and modern design requirements. Features like grooves, channels, and fastening points can be integrated directly into the profile, preserving design intent while streamlining fabrication and installation, reducing the need for secondary machining or additional components.

Deliver a High Strength-to-Weight Ratio

Custom aluminum extrusions optimize strength-to-weight ratios by placing material only where needed for structural performance. In door and window systems, this ensures panels remain rigid under wind loads and repeated use, while lighter profiles simplify handling and installation, meeting both performance and practical requirements efficiently.

Rather than relying on standard sections designed for broad use cases, custom profiles enable the fine-tuning of wall thickness and internal geometry. The result is a more efficient profile that supports performance needs without overusing material.

Ensure Durability and Corrosion Resistance

Long-term durability is better supported when alloy selection, profile design, and finishing are matched to site conditions. This is especially relevant in Philippine projects exposed to coastal humidity, salty air, or heavy rainfall.

Aluminum’s natural corrosion resistance can vary with application and finish. For projects exposed to harsh conditions, custom extrusions paired with anodizing or powder coating enhance durability and surface protection. Aligning the design with environmental demands minimizes premature wear and can reduce assembly time and labor by eliminating extra brackets or reinforcements.

Support Sustainability and Energy Efficiency

Improved sustainability starts with profiles designed to use only the material needed for strength and function. Because custom aluminum extrusions are application-specific, excess material and production waste can be minimized from the outset.

Beyond fabrication, custom profiles can also enhance building performance. Optimized geometries improve sealing and thermal behavior, reducing air leakage and heat transfer.

Combined with aluminum’s full recyclability, these efficiencies align with energy-conscious project goals. Over the life of the building, they can translate into lower operating costs without compromising durability.

Improve Cost Efficiency Over the Project Lifecycle

When evaluated across fabrication, installation, and maintenance, custom aluminum extrusions often deliver stronger cost efficiency over the project lifecycle. While tooling introduces upfront considerations, the downstream impact tends to offset them.

Standard profiles may require additional brackets, reinforcements, or machining to meet specific requirements. Custom extrusions can combine multiple functions into a single profile, reducing part counts and simplifying assembly.

Over time, these efficiencies help stabilize labor costs, reduce rework, and limit maintenance demands. For projects where predictability matters, this lifecycle view often makes custom solutions the more economical choice.

Projects That Benefit Most From Custom Aluminum Extrusions

Projects requiring precision, performance, or design flexibility often benefit from custom aluminum extrusions. AMC Aluminum provides tailored solutions to meet these specific demands. Common applications include:

- Architectural Applications: Unique designs that require specific shapes and sizes.

- High-Performance Structures: Buildings that demand enhanced strength and durability.

- Energy-Efficient Designs: Projects focused on sustainability and energy savings.

- Complex Assemblies: Applications where multiple functions can be integrated into a single profile.

These examples illustrate how custom aluminum extrusions can be designed to address specific requirements, simplify construction, and support project goals. By partnering with AMC Aluminum, you can access expertise and solutions that help match your design and performance needs without relying solely on standard profiles.

Key Takeaway

There are many reasons why builders prefer custom aluminum extrusions and with and with a better understanding of project requirements, performance needs, and long-term benefits, you can make informed decisions that optimize both design and efficiency.

When it comes to custom aluminum extrusions, AMC Aluminum has the solutions you need. Our products deliver precise fit, durability, and project-specific customization for modern builds. Get in touch with us today to learn how our extrusions can support your construction projects.

.jpg)

.jpg)

.jpg)