What are the factors that affect aluminum extrusion prices in the Philippines?

- Raw materials

- Production costs

- Supply chain dynamics

- Economic factors

- Material quality

- Manufacturer specifics

Overview

- Aluminum extrusion prices in the Philippines are shaped by multiple factors, including raw material costs, production complexity, supply chain dynamics, economic conditions, material quality, and manufacturer efficiency.

- Understanding these interconnected drivers enables developers and fabricators to plan budgets accurately, minimize risks, and make informed decisions for cost-effective, high-quality construction projects.

Aluminum pricing is influenced by a combination of global market trends and local production conditions. The cost of aluminum extrusion, the process of shaping the alloy into high-strength profiles, adds another layer to pricing due to the specialized steps involved in manufacturing.

These profiles are essential in modern construction, making it crucial to understand the factors that affect aluminum extrusion prices in the Philippines. Understanding these drivers helps developers and fabricators anticipate market fluctuations and plan budgets with greater accuracy.

This article examines the key factors influencing extrusion costs in the Philippine market, offering insights to support more informed purchasing decisions.

Raw Materials

The cost of aluminum ingots is the primary factor in estimating aluminum extrusion prices, as prices fluctuate daily on global commodity exchanges. Local suppliers adjust their quotes accordingly, making raw materials the largest component of the final cost.

The quality of the raw aluminum also directly impacts structural integrity. Using high-grade primary alloys ensures stronger, more durable profiles. For example, selecting 6063 aluminum for window frames balances strength and weight, meeting construction requirements while maintaining safety standards.

Monitoring global market trends for aluminum helps developers and fabricators anticipate price changes, allowing more accurate budgeting and reducing the risk of unexpected cost increases during production.

Production Costs

The design of aluminum profiles affects manufacturing costs. Intricate shapes need precise custom steel dies, raising initial expenses but reducing on-site errors, adjustments, and material waste.

Beyond design complexity, operational expenses such as electricity for high-temperature extrusion and the cost of skilled labor play a significant role in determining per-kilogram pricing. These factors collectively influence the overall cost of producing high-quality aluminum profiles.

Supply Chain Dynamics

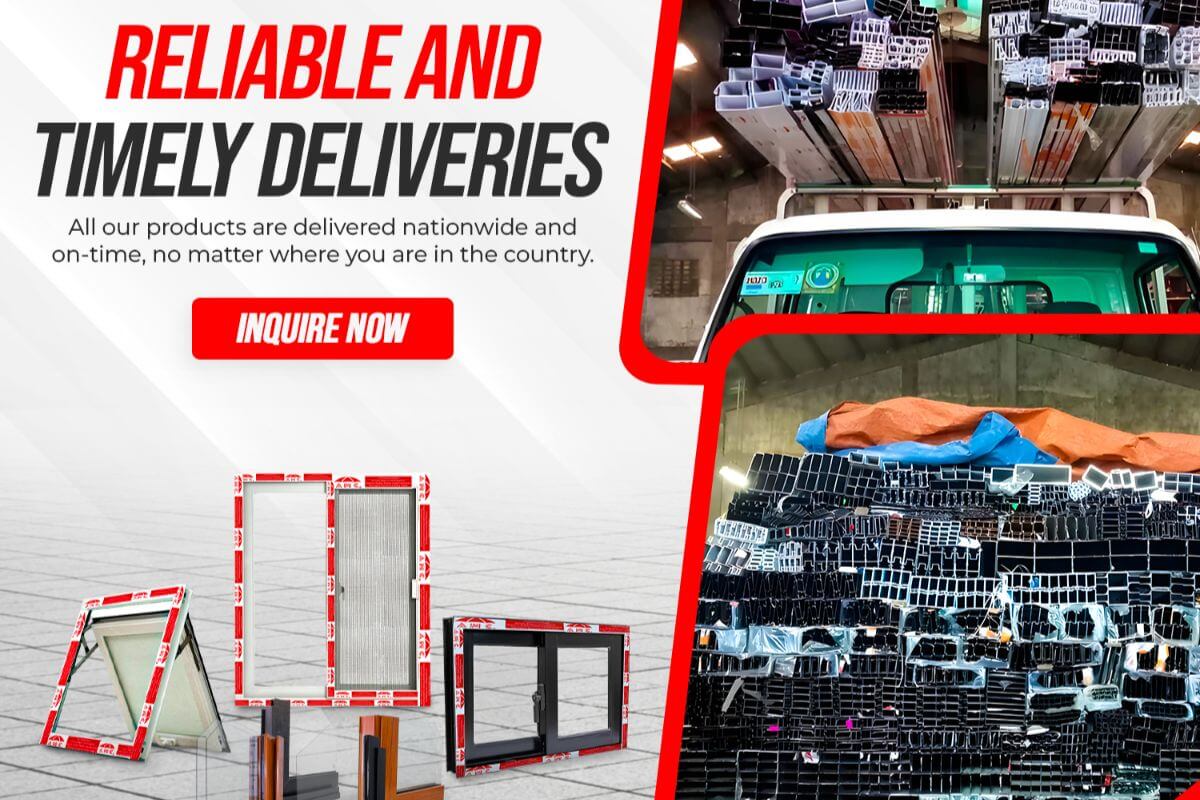

The supply chain is a critical factor affecting aluminum extrusion prices in the Philippines. Local suppliers depend heavily on imports from global smelters, meaning disruptions abroad can directly influence availability and cost. Efficient supply chain management ensures projects stay on schedule and within budget.

Key aspects include:

- Import Dependency: Local suppliers rely on imported aluminum. Any delays or shortages from global smelters can increase costs and affect project timelines.

- Supply and Demand: High-demand construction seasons can tighten inventories, creating temporary price premiums as multiple projects compete for limited materials.

- Shipping and Logistics: Aluminum profiles are heavy and require careful handling, transportation, and storage. Freight charges, port fees, and warehouse management all contribute to overall costs.

Understanding these dynamics helps developers and fabricators plan procurement more effectively. Strategies such as ordering materials ahead of peak demand or working with suppliers who maintain reliable shipping networks can stabilize costs and prevent delays.

Economic Factors

Global economic factors also influence aluminum pricing in the Philippines. Fluctuating exchange rates impact the cost of imported raw materials, while trade policies, tariffs, and local tax regulations affect overall market stability. Incorporating these economic variables into your procurement strategy helps minimize the risk of unexpected cost increases.

- Exchange rates: A weaker Philippine peso against the US dollar raises aluminum prices locally, as most raw ingots are imported and priced in USD.

- Economic policies: Policies like import tariffs or subsidies on raw aluminum directly raise or lower extrusion costs.

Material Quality

Selecting the right alloy ensures that finished profiles can withstand the demands of construction. For instance, 6063 aluminum balances strength and weight, making it ideal for residential window frames and door assemblies.

Surface treatments such as powder coating or anodizing add another layer of protection against the humid Philippine climate and coastal salt air. Investing in quality finishes preserves both the durability and appearance of your structures, reducing maintenance costs and extending the life of your investment.

Manufacturer Specifics

The choice of manufacturer significantly impacts aluminum extrusion prices and project efficiency. Experienced manufacturers can stabilize costs by optimizing large-scale production processes and implementing advanced scrap recycling techniques. These practices reduce material waste, improve operational efficiency, and provide more predictable pricing without compromising product quality.

Working with a reliable manufacturer also streamlines project workflows. Facilities that offer in-house services such as cutting, coating, and finishing minimize the labor required on-site, helping teams meet tight construction deadlines and reducing potential delays.

Other factors to consider include:

- Volume Discounts: Transparent communication about bulk pricing allows for better budgeting and resource allocation.

- Process Efficiency: Manufacturers with standardized procedures and quality control ensure consistent product quality across large orders.

- Flexibility and Support: A responsive supplier can adapt to design changes or urgent requests, keeping projects on track.

Key Takeaway

Aluminum extrusion costs in the Philippines are influenced by interconnected factors: raw materials, production complexity, supply chain dynamics, economic conditions, material quality, and manufacturer efficiency. Recognizing how each element affects the next allows developers and fabricators to plan budgets more accurately, avoid surprises, and make informed decisions.

Plan your projects with confidence using AMC Aluminum’s expert guidance on aluminum extrusion. Our team helps you estimate costs accurately, ensuring efficient budgeting and smooth execution for large-scale builds. Contact us today to learn more about our solutions.

.jpg)

.jpg)

.jpg)