What are the effects of alloying elements on aluminum?

- Silicon

- Copper

- Manganese

- Magnesium

- Zinc

- Chromium

- Nickel

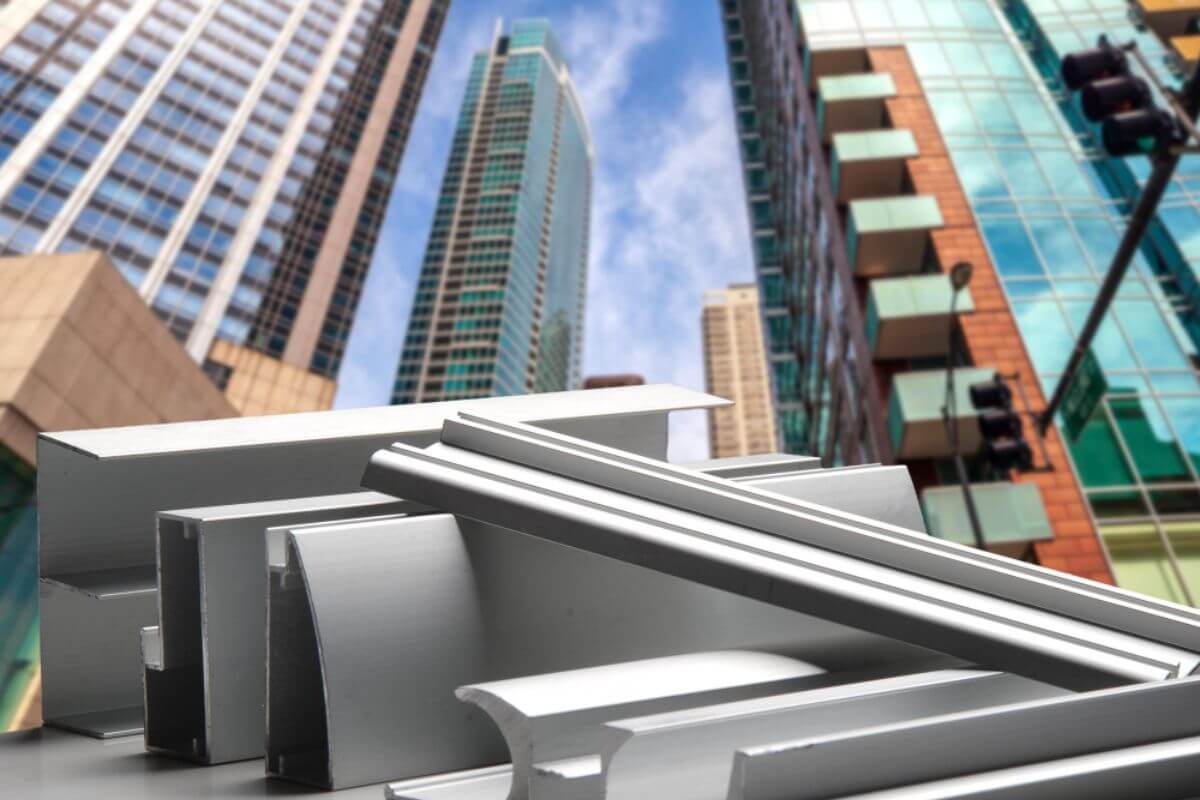

For the longest time, aluminum has been valued for its durability, corrosion resistance, and for being lightweight. However, certain industrial and construction applications have started to have more material demands. As a solution, the effects of alloying elements on aluminum are being further explored.

It is becoming more common for other elements to be alloyed with aluminum in order to achieve various mechanical and physical properties required for specific applications.

When alloyed with other elements, aluminum can have properties ranging from improved thermal conductivity, tensile strength, to better weldability. Doing this can make the fabrication of aluminum profiles much easier and often enhance the lifespan of the product.

This being said, it is important to understand the effects of alloying elements on aluminum. Continue reading on to learn more.

Silicon

Thermal stability is a key feature that determines the suitability of aluminum to high-temperature applications. Aluminum can be thermally unstable with its properties being composed over a certain temperature and period of time. The good news is, the alloy of silicon and aluminum can reduce temperature melting points and increase fluidity. This reduces shrinkage during application. In addition, the lower shrinkage improves castability.

The applications of silicon alloyed with aluminum include those that are exposed to high temperatures. For example, commercial planes with aluminum components and aluminum packaging and transportation materials that are exposed to slightly elevated temperatures during travel as well as aluminum automotive engine parts.

Copper

With the alloy of copper and aluminum, there are typically residual amounts (2% to 10%) of the copper present with other elements. This allows improving the tensile strength and hardness of the alloys due to precipitation hardening. Moreover, this enhances corrosion resistance, ductility, and heat treatability. For this reason, copper and aluminum alloys are commonly used in aerospace and automotive applications. Most military vehicles and rocket fins are made with this.

Manganese

Manganese is another alloying element used to achieve certain properties in aluminum. Manganese increases the recrystallization temperature as well as the strength of aluminum-based alloys. There is also a noticeable improvement in corrosion resistance with this alloy. Some of the common uses of manganese and aluminum alloys include heat exchangers, piping systems, utensils, and radiators.

Magnesium

Magnesium increases the tensile strength of aluminum without decreasing ductility. This also improves corrosion resistance. And in combination with other elements like silicon or zinc, it retains strength when used on non-heat-treatable materials through precipitation hardening. This is a versatile alloy that can be found in extensive applications that involve extruding shapes.

Aluminum and magnesium are commonly produced as sheets and plates. They are also used extensively for structural fabrications. The applications of the alloy include bicycle and automotive frames, chemical tanks, pressure vessels, shipbuilding parts, and scaffolding.

Zinc

The mixture of zinc and aluminum offers the greatest tensile strength among all aluminum alloys. To add to that, when combined with other elements like magnesium and copper, this allows heat treatability without decreasing strength. Zinc enhances the potential of aluminum in various ways, which makes it ideal for protective cladding and other structural applications. It’s important to take note, however, that zinc and aluminum alloys are vulnerable to stress corrosion cracking.

Chromium

The effect of aluminum and chromium alloys is to control grain structure. This means grain growth and recrystallization are suppressed during heat treatment. Similar to the effect of manganese, chromium will improve the ductility and strength of aluminum alloys (e.g., aluminum-silicon). Chromium is also added to aluminum alloys to improve their corrosion resistance and strength. As a result, this reduces the susceptibility of

stress corrosion resistance.

Nickel

Nickel is an element commonly alloyed with aluminum to increase hardness and tensile strength. To add to that, nickel aluminum alloys benefit from reduced thermal expansion.

This is why nickel aluminum alloys are a popular choice for industrial applications including landing gear bearings, propeller hubs, marine hardware, vertical pump column pipings, and fire suppression systems.

Key Takeaway

The effect of alloying elements on aluminum varies from improved corrosion resistance to increased tensile strength, which makes them crucial for various industrial applications. With different alloying elements available, there is a perfect option for your application on hand.

Still unsure on what aluminum alloy to use for your project? Check out AMC Aluminum’s products. As the leading aluminum manufacturer in the Philippines, our aluminum profiles are composed of manganese, silicon, copper alloys, to name a few. Click here to check them out or contact us for other inquiries.

.jpg)

.jpg)

.jpg)