What are the uses of aluminum in the electrical industry?

- Electrical busbars

- Power cables and overhead lines

- Induction motors

- Device cases

- Heat sinks

- Transformer sinks

Aluminum’s versatility is apparent in industries such as construction, medical, manufacturing, automotive, and aeronautical. Another industry that benefits from aluminum is electrical manufacturing. So what exactly are the most popular uses of aluminum in the electrical industry? Learn more.

Electrical Busbars

In electric power distribution facilities, busbars refer to the electrical metal bars housed inside panel boards, switchgear, and enclosures. Busbars are used to carry high amounts of current to circuit breakers. Since 1960, electrical busbars have been made with aluminum.

As one of the lightest alloys, a single operator can easily install light aluminum busbars. And given their customized extruded profiles, aluminum busbars can slide easily and securely into position.

Busbars can also be made with copper. However, aluminum busbars are 50% more conductive. Combined with their lightweight, aluminum busbars provide 50% electrical conductivity per mass.

Aluminum can also withstand high amounts of currents of up to 4000A. That’s enough to resist thermal expansion which can completely damage busbars.

Power Cables and Overhead Lines

One of the most common uses of aluminum in the electrical industry is power cables and overhead lines.

Since the development of aluminum wiring back in the mid-1960s, power cables and overhead lines have been made with this material. While copper electrical wiring was also widely used, it has since skyrocketed in price. Aluminum is an abundant metal and it is also easy to fabricate, which ultimately lowered its cost for end consumers.

Power cables and overhead lines have long been the primary method for transferring electricity across varying distances. As said earlier, aluminum is also more conductive than copper. It can distribute energy more efficiently.

Aluminum is also the best material for power cables and overhead lines because it can withstand harsh environments. If you don’t already know, power cables and overhead lines are subject to heavy winds, direct sunlight, and even storms. Aluminum is corrosion-resistant, so it’s ideal for outdoor use. It is also a metal that has excellent tensile strength.

Induction Motors

Induction motors are alternating current (AC) electric motors that use electromagnetic induction from the stator windings. These are mainly used in pumps, compressors, fans, air conditioners, refrigerating devices, drilling machines, and automobiles.

Aluminum is commonly used in making induction motors. Even the cage rotor for induction motors and crankcases utilize aluminum bars. Cage rotors for induction motors often use aluminum bars. The lower weight for better conductivity of aluminum makes it the ideal material for the alternative current of induction motors.

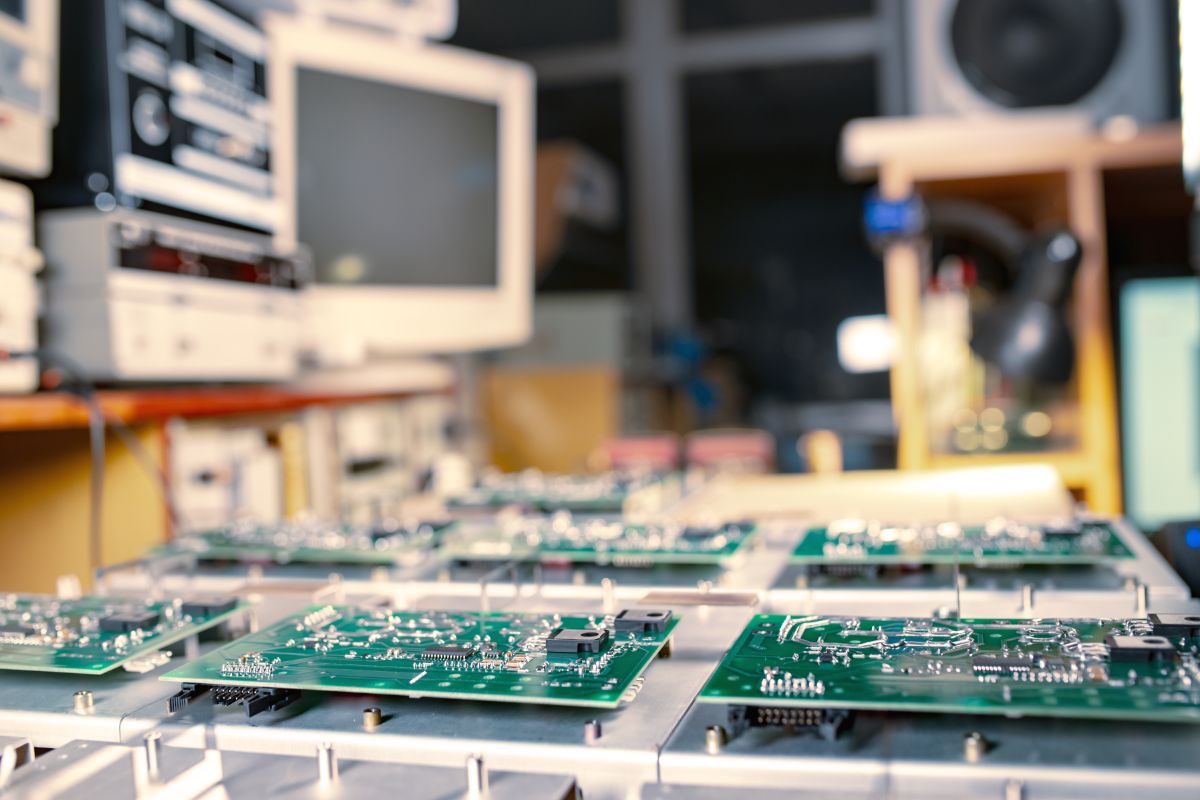

Device Cases

When it comes to the casing for different electronic items and devices, aluminum is also one of the most popularly used materials. Some of the items and devices that commonly use aluminum casings include laptops, gaming consoles, smartphones, digital cameras, digital watches, and even televisions.

Compared to using flimsy plastic casing and heavy metal casing, aluminum casing is the best option because it is durable, lightweight, and cost-effective.

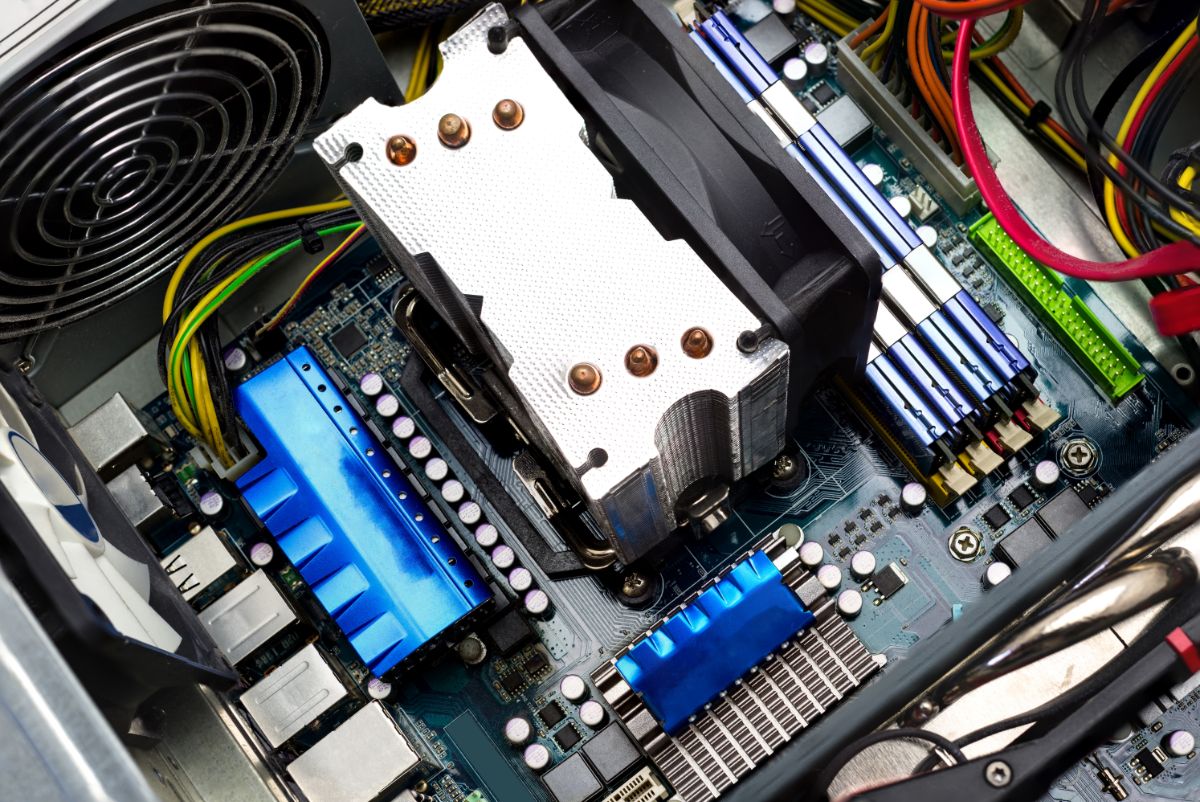

Heat Sinks

As said earlier, aluminum is highly ductile and has high thermal conductivity. It’s a material that can easily be extruded with integrated fins into either solid or hollow shapes. This makes it ideal for forming heat sinks. Heat sinks are components that passively transfer heat generated by an electronic or mechanical device. They achieve this by increasing a device’s surface area. As a result, the heat scatters away from the device.

In computers, heat sinks are used to cool down GPUs, CPUs, chipsets, and RAM modules. Heat sinks are also used to regulate the temperature of power transistors, lasers, and light-emitting diodes (LEDs).

Transformer Tanks

Transformer tanks are used to hold, protect, and cool the core and the winding of electrical transformers. The durability of aluminum makes it ideal for the body of transformer tanks. As an added benefit, aluminum is lightweight enough for mounting pole transformer tanks.

Key Takeaway

Aluminum is one of the most common metals used in diverse applications across different industries. Due to being lightweight, corrosion-resistant, durable, and electrically conductive, aluminum is also highly relied on when making electric products. In this article, we’ve rounded up some of the common uses of aluminum in the electrical industry.

If you need any aluminum profile or aluminum accessory in the Philippines, check out our products at AMC Aluminum! For over 20 years, we have been producing aluminum products made from ISO grade quality billet extruded with the latest Taiwan machinery. For more inquiries, contact AMC Aluminum here!

.jpg)

.jpg)

.jpg)