What are the different uses of aluminum in construction?

- Wall cladding

- Window frames

- Ventilation

- Studs

- Latches

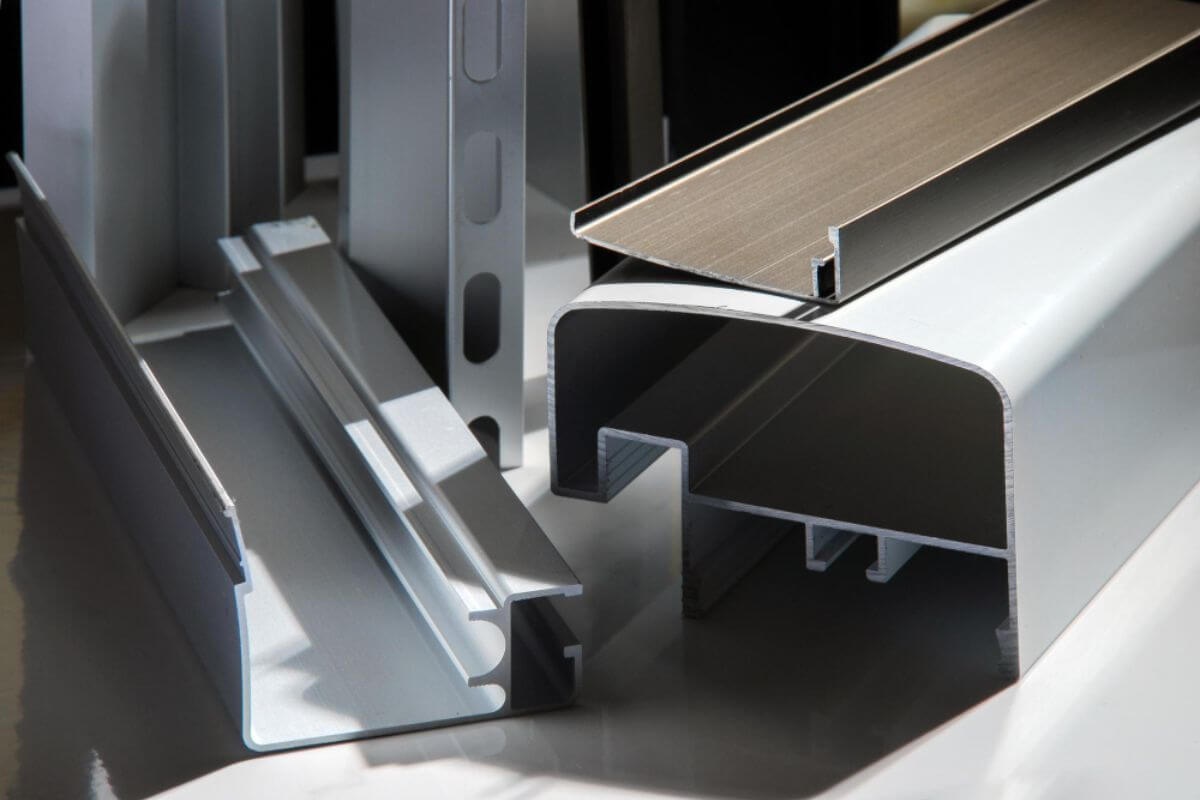

Compared to other building materials like steel, wood, or stainless steel, aluminum is more lightweight, making it ideal for all kinds of applications. For aluminum, its uses in construction can range anywhere from structural or simply decorative purposes. Some of its most common include window frames, door frames, and louvers. But it’s also a good alternative for wall cladding/panelling, ventilation, heating and cooling systems, latches, studs, and railings.

Mined from an ore known as bauxite, aluminum has proven to be an effective alloy for construction. While it may not have greater mass that is typical of construction materials, it’s a formidable choice due to its combined durability and low weight. Read on to learn more.

Wall Cladding

Homeowners and building owners may think that panelling or cladding only has decorative implications on their structures. However, this isn’t always the case — cladding also has a number of advantages, such as improved ventilation, acoustics, and greater resistance against physical impacts.

Aluminum is a perfect wall cladding material due to its ease of installation, cost-effectiveness, and machinability. Manufacturers can fabricate a wide variety of aluminum panelling designs that can meet the customer’s needs. Making any modifications to the design is also possible by using different metal fabrication and cutting techniques that are all effective on aluminum.

For aluminum cladding, sheets are often used, but you may also get creative with your design. AMC Aluminum’s high-quality aluminum products such as flat bars and tubes can easily be combined together as part of your interior or exterior wall cladding.

Window Frames

Like steel, aluminum also has an excellent strength to weight ratio. This means that only few quantities of this material are required to achieve a similar weight for the same strength — unlike timber or plastic.

With this in mind, another popular constructional use of aluminum is the low-profile aluminum window frame. Low profile, meaning it doesn’t take too many aluminum components in order to form a single aluminum window frame. This has several implications — for one, it’s budget friendly since building owners don’t have to buy a high volume of materials. And second, despite the low profiles, the window frames are still able to have the same sturdiness without any quality drawbacks.

For your aluminum window frames, AMC Aluminum has a wide production selection to choose from. You can opt for standard window frame profiles, awnings, or sliding windows, depending on your preferences.

Ventilation

Ventilation may often be disregarded, but it’s essential for any kind of building. Proper ventilation structures and systems ensure that a building’s inhabitants are comfortable. This means that the heat exchange process is working optimally to regulate temperature inside the building. Poor ventilation design can lead to stuffy or cold interiors that will make any building not conducive for occupancy.

As much as the ventilation design is important, it’s also crucial that the right materials are used for the job. Aluminum tubing, for example, can serve as efficient ventilation tubings or passageways where gas exchange takes place.

The material is non-corrosive, which leads to infrequent maintenance and repair. Lack of corrosion also entails that all kinds of gasses and fluids can safely pass through the ventilation tubing without damaging nearby components — be it electrical or structural.

Studs

Like the framework, building studs provide stability and design to the entire structure. They may be used to support other loads such as ceiling or roofing weight or they may simply be used as partitions for different areas inside a room.

Wooden studs are the convention, but they may not really hold up in all kinds of environmental conditions — especially in wet areas or portions where moisture is frequent. For this reason, building owners turn towards metal studs, like aluminum, which does not get affected by moisture.

Aluminum studs can also be installed and designed in various ways. You can have them cut in different lengths to fit any room size or have them powder coated for better protection against the elements.

Latches

In small scale constructional uses, aluminum can also come in the form of flat bars. Once cut to size, these flat bars can undergo further fabrication in order to become gate latches.

Aluminum latches help combine the bold and lock system of any door or gate. Oftentimes, the trouble with other types of latches is that they tend to have a faster wear and tear — particularly if they’re made of corrosive materials.

Meanwhile, this is not a problem in aluminum latches. As mentioned before, aluminum doesn’t corrode — having aluminum latches for any gates/doors inside and outside a building can lessen the effort required in buying new parts and replacing components altogether.

Key Takeaway

A choice building material for many projects is aluminum. Its uses in construction can range from window frames, wall cladding, ventilation tubing, latches and studs. For all of its lightweightness, aluminum is a material that surprisingly doesn’t compromise on quality, cost, and durability. When planning for a building project in the future, you can’t go wrong with choosing aluminum.

In need of high quality aluminum accessories and products? The leading aluminum supplier and manufacturer, AMC Aluminum, has a wide selection to choose from. Click here! You may also contact them for more information.

.jpg)

.jpg)

.jpg)