Overview

- Custom aluminum extrusions for specialized designs offer precision, flexibility, and efficiency, enabling complex, high-performance profiles for construction, transportation, industrial, and consumer applications.

- Advanced manufacturing processes and reliable partners ensure consistent quality, reduced part counts, and streamlined production.

- AMC Aluminum delivers tailored solutions that meet strict specifications and support long-term project success.

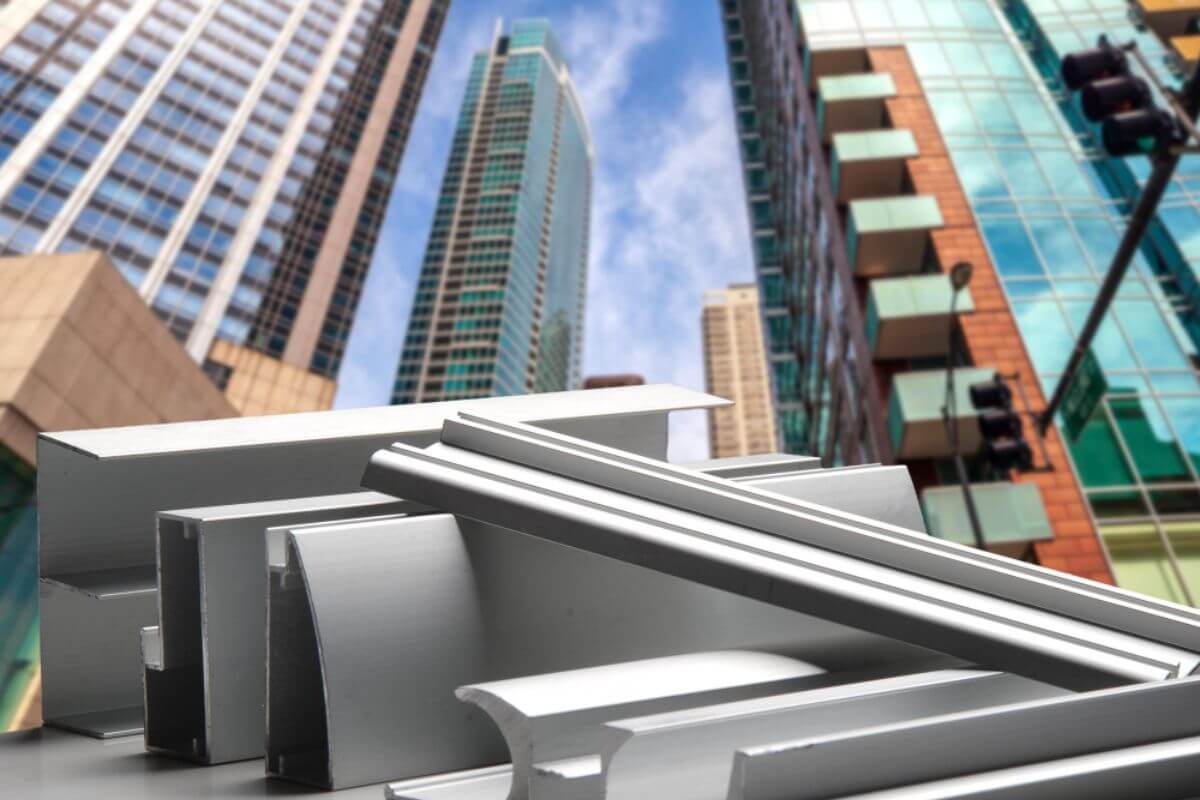

As modern construction and industrial engineering advance, the need for materials that accommodate high-level customization has grown significantly.

Custom aluminum extrusions for specialized designs have become the ideal solution, offering both structural strength and design flexibility to turn complex concepts into functional, visually appealing results.

This article explores how these extrusions can be engineered into custom profiles to elevate project outcomes. It also highlights how working with a reliable partner can streamline production, reduce costs, and ensure timely delivery for specialized, high-precision applications.

What You Need to Know About Custom Aluminum Extrusions

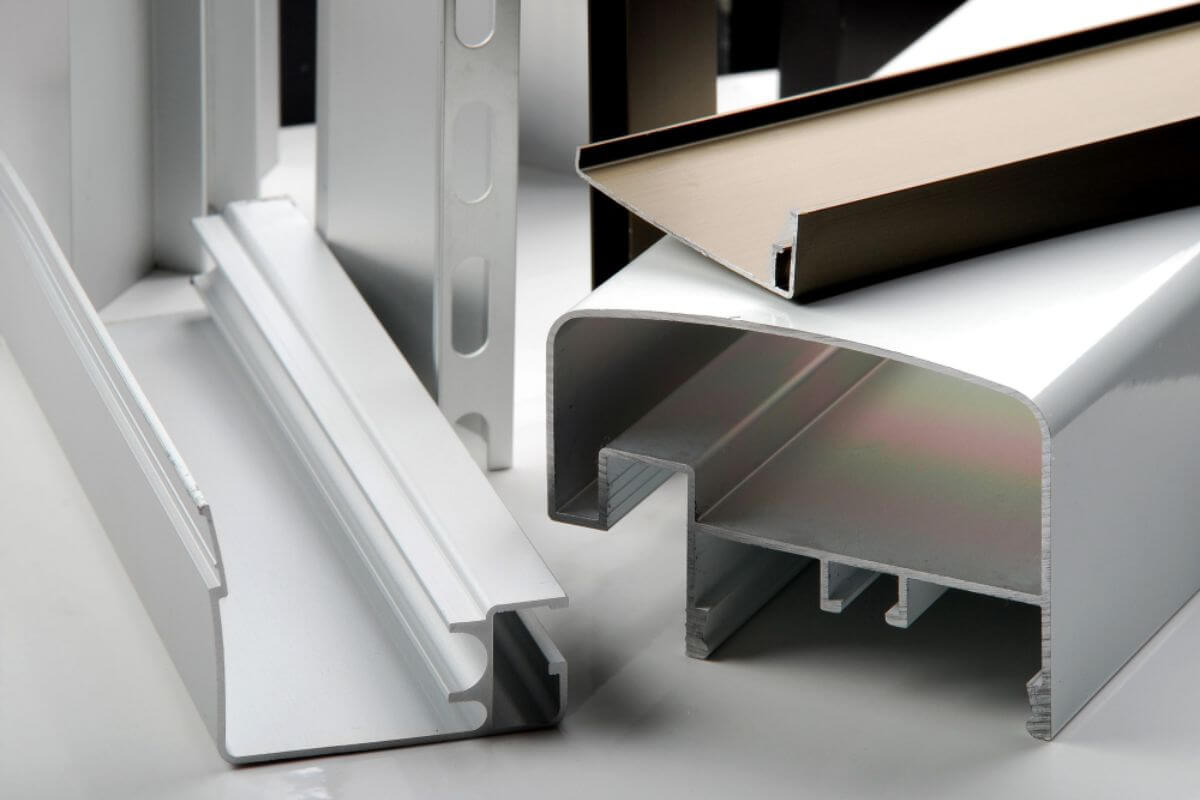

Aluminum extrusions are components formed by heating aluminum billets and forcing them through a shaped die. This process creates precise profiles used in construction, automotive, electronics, and many other industries worldwide. This is favored for extrusion because it is lightweight, strong, versatile, and highly adaptable to different applications.

Definition

Custom extrusions are tailored aluminum profiles formed by pushing aluminum billets through a custom-designed steel die, creating intricate cross-sections to exact specifications.

Process

Heated aluminum is extruded, cooled, and then can undergo further fabrication like cutting to length, drilling, bending, anodizing, or powder coating to meet unique project needs.

Benefits of Aluminum Extrusions for Specialized Designs

For specialized designs that demand precision, flexibility, and consistency, aluminum extrusions offer practical advantages that support both creative freedom and real-world performance. Here’s how:

Design Freedom

Engineers and designers gain exceptional flexibility with aluminum extrusion, surpassing the limitations of standard, off-the-shelf components. This technique enables the creation of complex geometries, intricate details, and virtually any cross-sectional shape required for a project.

This capability allows teams to develop highly specialized solutions tailored to functional, structural, and aesthetic requirements. Whether producing lightweight structural elements, integrated channels for wiring or fluids, or decorative architectural features, custom aluminum profiles turn conceptual designs into practical, high-performance components.

Such adaptability serves not only as a technical advantage but also as a strategic asset. It empowers businesses to innovate, differentiate their offerings, and maximize performance while maintaining efficiency in manufacturing and assembly.

Performance

Instead of relying on general-purpose materials, designers can choose from a broad selection of aluminum alloys matched to specific performance requirements. The adaptable 6000 series supports a wide range of structural applications, while the high-strength 7000 series delivers the durability required for aerospace and other demanding environments.

Material performance extends beyond alloy selection alone. The extrusion process supports advanced heat treatment options that further refine mechanical and functional properties. These treatments can strengthen structural integrity, improve thermal dissipation, or support high electrical conductivity, allowing each profile to perform at its full potential within its intended application.

Efficiency

Aluminum extrusions offer a unique opportunity to combine multiple functions within a single, high-performance profile. Incorporating features such as screw ports, internal channels, and snap-fit joints directly into the design allows engineers to reduce total part counts significantly.

This integration transforms a simple structural element into a multifunctional component. Custom profiles provide a more efficient production process, ensuring specialized designs are easier to manufacture and more durable in real-world applications.

Precision

Advanced die engineering and carefully controlled cooling processes enable manufacturers to achieve consistent dimensions throughout extended production runs. This level of control ensures that each profile meets exact specifications, even at high volumes.

Such precision is critical in specialized industries, where minor dimensional variations can compromise fit, performance, or long-term reliability. Maintaining tight tolerances supports seamless assembly, reduces rework, and upholds the quality standards required for high-performance applications.

Common Applications

Custom aluminum extrusions are widely used because they adapt easily across industries. Learn about how these are applied on the following:

- Architecture: Extrusions are utilized to create high-performance curtain walls and unique framing systems that support expansive glass surfaces with minimal weight.

- Transportation: In the automotive and transit sectors, extrusions are engineered into lightweight chassis and roof rails to improve fuel efficiency without compromising safety.

- Industrial: Manufacturers utilize custom extrusions to build modular machine frames and automation components that require precise alignment and easy reconfiguration.

- Consumer goods: Extrusions are used to produce sleek, durable enclosures for electronics and unique product designs.

Why Choosing a Reliable Aluminum Extrusion Manufacturer Matters

A trusted partner provides more than just raw materials; they offer the technical expertise to maintain material consistency. Choosing a manufacturer with a proven track record ensures that your components are built to survive the rigorous demands of their intended environment.

In the Philippines, AMC Aluminum stands as a premier example of a reliable industry leader, leveraging over two decades of expertise to support domestic and international projects. By utilizing state-of-the-art machinery and ISO-grade quality standards, we ensure that every extrusion meets the exact specifications our clients need.

Key Takeaway

Custom aluminum extrusions empower engineers and designers to move beyond limitations, creating a purpose-built solution. When execution matters as much as design intent, partnering with an experienced manufacturer is essential.

At AMC Aluminum, specialized extrusions are engineered with consistency, technical expertise, and long-term reliability to support demanding projects across industries. Reach out to us to discuss your project requirements.

.jpg)

.jpg)

.jpg)