Overview

- Aluminum profile pricing depends on raw material costs, production complexity, and compliance with quality standards. Market trends, demand, and supplier reputation also influence value.

- Choosing certified, high-grade profiles ensures durability, consistent performance, and long-term cost efficiency.

- AMC Aluminum provides top-quality, standards-compliant profiles, helping professionals achieve reliable results and protect their investment.

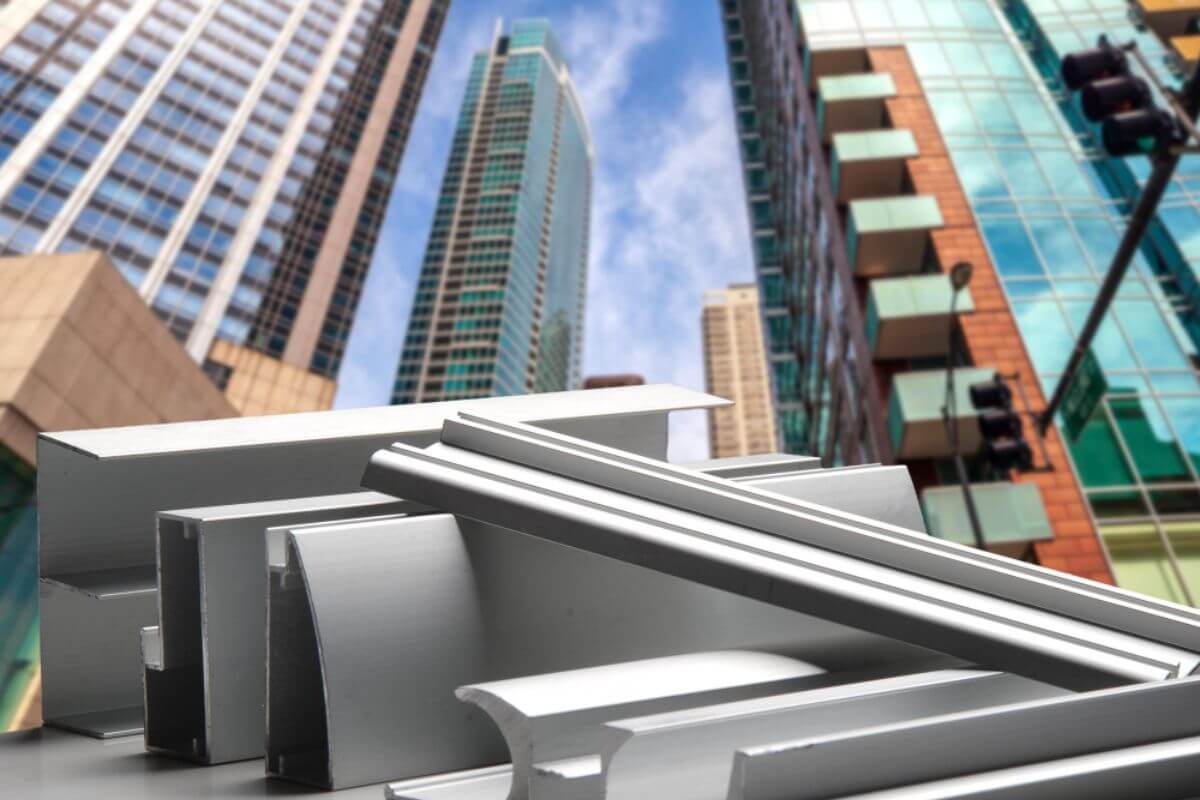

Every aluminum-centric project begins with one essential question: how much will the materials cost? Profiles form the backbone of structural stability and long-term value. For developers and fabricators, understanding the factors that influence the pricing of aluminum profiles is crucial for acquiring quality materials within budget.

Aside from market trends and quality, profiles that meet stringent specifications also come at a premium.

AMC Aluminum, a trusted supplier in the Philippines, provides top-grade, standards-compliant profiles that help professionals achieve cost-efficiency and reliability. Continue reading to learn more.

Raw Material and Production Costs

Aluminum profile prices depend on raw material costs and fabrication processes. Market fluctuations in aluminum, a traded commodity, directly impact production expenses. Professionals should monitor both metal prices and manufacturing efficiency to anticipate and manage potential price changes effectively.

Aluminum Ingot Prices

Since aluminum ingots serve as the base input for every profile, the slightest change in their market price immediately raises production expenses. Manufacturers often adjust their selling prices when global supply tightens to maintain profitability. Professionals need to monitor raw aluminum rates to help forecast spending and secure stable procurement terms.

It’s also important to note that the impact of ingot prices also connects to material standards. Certified suppliers invest in purer, high-grade ingots to meet compliance requirements. While these may increase initial costs, they ensure consistent mechanical strength and longer-lasting quality for construction and fabrication alike.

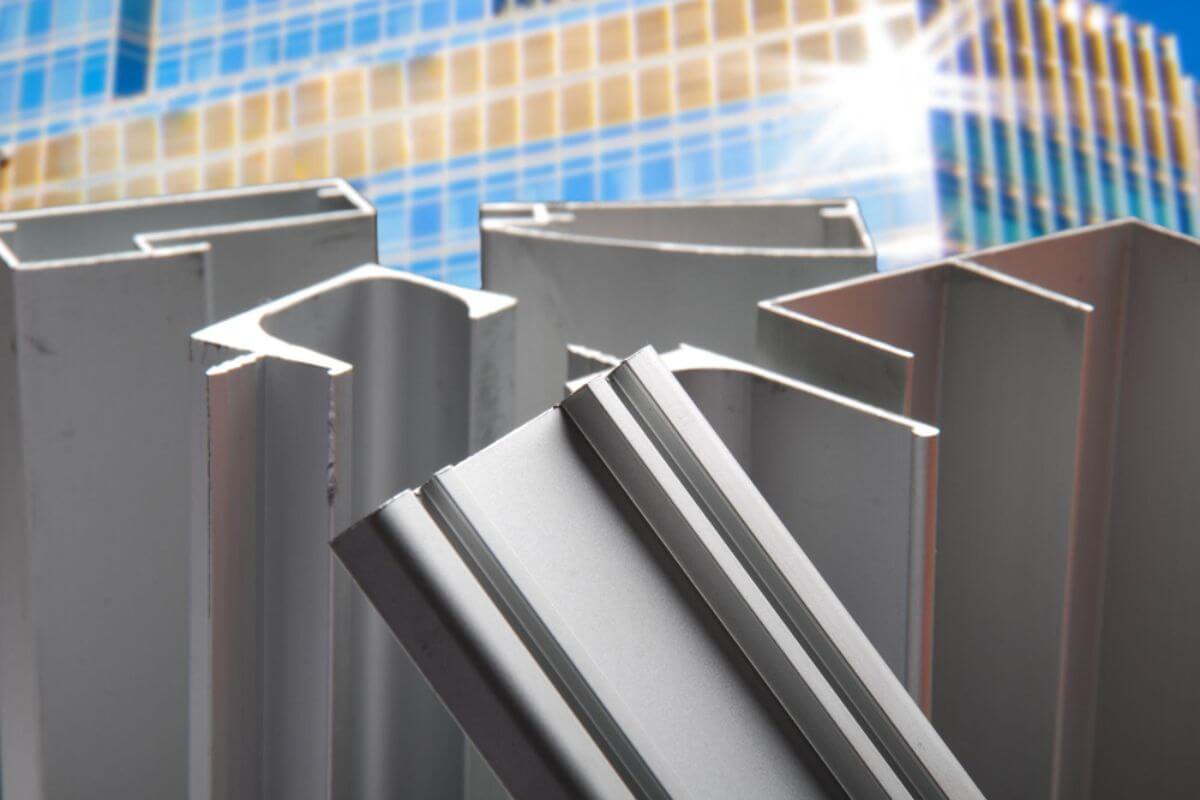

Production Complexity

The more intricate the production process becomes, the higher the resulting cost per profile. Complex designs or precise tolerances all demand additional machining, which reflects in the final price. Fabricators who want detailed, custom extrusions need to consider how manufacturing effort translates to overall value.

Compliance also affects this stage, as standardized production ensures every section meets consistent strength and alignment requirements. This reduces the likelihood of fabrication errors. Not only does it support faster installation, but it also requires fewer reworks, which allows developers to balance budget and construction timelines.

Market and Economic Factors

Aside from production requirements, external economic movements also affect how suppliers set aluminum profile prices. Factors such as exchange rates, inflation, and trade policies can alter material costs and affect supply chains.

Staying aware of these shifts helps manage sourcing strategies and avoid unexpected budget strain.

Supply and Material Demand

When demand rises faster than supply can meet it, manufacturers are compelled to increase prices to balance availability. This often happens during construction booms or when industries compete for the same metal resources. Planning purchases during steady demand periods allows for better pricing predictability.

Profiles that meet certified performance benchmarks are less likely to fluctuate in availability. Since reputable manufacturers maintain steady production quality, construction and production teams gain access to reliable inventory during tight market periods. Choosing a compliant supplier is the key to getting the best value out of material investments.

Competition

Competitive pricing pressures often limit how much companies can charge for their profiles. Businesses must balance affordability with maintaining quality assurance standards. Professionals benefit from this environment, as it allows them to compare certified options that meet required strength and durability levels.

On the other hand, extreme price competition can lead some suppliers to cut corners. Lower-cost profiles might omit standard compliance and use weaker alloys, resulting in subpar performance. Selecting trusted suppliers like AMC Aluminum ensures that pricing remains competitive without compromising the profile’s industry-grade qualities.

Profile Characteristics and Other Factors

Pricing isn’t determined by market trends and material quality alone; brand perception also influences value. The combination of material grade and manufacturing reputation defines a profile’s true worth, helping professionals select products that ensure durability, performance, and long-term benefits.

Brand and Supplier Reputation

Well-established brands put higher price tags on their profiles because their credibility assures customers of consistent performance and quality. Their long-standing adherence to testing and certification standards differentiates them from cheaper, unverified sources.

In addition, reputable suppliers continuously innovate their processes to comply with the latest building standards. AMC Aluminum, for instance, upholds strict quality management systems to ensure each product meets performance and sustainability standards. Choosing such a brand enhances both your project’s value and your alignment with responsible building practices.

Physical Properties

Profiles with greater material use, tighter tolerances, or specialized finishes are priced higher due to the precision and complexity involved in production. Thicker walls and custom dimensions enhance mechanical performance, making them ideal for high-use or weather-exposed structures.

Material standards further ensure durability by specifying minimum thickness and coating adhesion. Profiles meeting these benchmarks, such as the WYC Series, resist deformation and corrosion, maintaining both appearance and functionality. Choosing high-quality profiles guarantees long-lasting structural performance and protects your investment over time.

Key Takeaway

Understanding the factors that influence the pricing of aluminum profiles allows developers and fabricators to make purchasing decisions that protect their budget. Each element, from raw materials to profile specifications, directly ties back to how standards define their long-term reliability.

When you prioritize compliance, you invest in products that deliver consistent results over years of use. AMC Aluminum combines high-quality top-grade materials and advanced processes to help you achieve reliable performance in every project. Contact us today to learn more about how our profiles can enhance your next project.

.jpg)

.jpg)

.jpg)