What should you consider when choosing aluminum profiles for architectural uses?

- Alloy grade and composition

- Profile design and shape

- Thickness and structural strength

- Surface finish options

- Long-term performance and durability

Overview

- This article outlines key considerations when choosing aluminum profiles for doors and windows, including alloy selection, profile geometry, wall thickness, surface finish, and environmental factors.

- It explains how proper specification enhances durability, performance, and installation efficiency while minimizing costly errors. AMC Aluminum offers standard and customizable solutions to meet diverse architectural requirements.

When specifying aluminum for architectural elements for doors and windows, factors such as design, site conditions, and intended use directly impact performance and installation efficiency. Early evaluation of alloy, profile design, tolerances, finishes, and structural capacity helps ensure the material meets both aesthetic and engineering requirements while avoiding costly project issues.

To help you choose, this article outlines the things to consider when choosing aluminum profiles for architectural use, presenting practical checkpoints and specification tips that reduce installation mistakes and support long-lasting, high-quality outcomes.

Alloy Grade and Composition

Alloy selection directly affects an aluminum profile’s strength, corrosion resistance, and workability. For most architectural doors and windows, 6000 series alloys—particularly 6061 and 6063—offer the best balance of durability and ease of fabrication. Their silicon and magnesium content provides moderate strength and corrosion protection, making them ideal for versatile applications. In contrast, 7000 series alloys deliver higher strength but are less suitable for standard welding. Reviewing alloy and temper data ensures the chosen material performs reliably over time.

At AMC Aluminum, we offer a variety of profiles designed with your architectural requirements in mind, including:

- AMWSD Series: Sliding window profile with double jamb, head, interlocker, and screen, designed to keep water out and prevent drafts.

- Premium 75 Series: Lightweight and versatile profiles for sliding windows, casement doors, and awnings, equipped with multi-lock systems for lasting durability.

- ED Section: Sturdy profiles for commercial doors with bullnose glass window trim, available with standard or P-threshold options.

- RCW series: Curtain wall or mullion profiles designed for all-glass designs in high-rise buildings or home renovations.

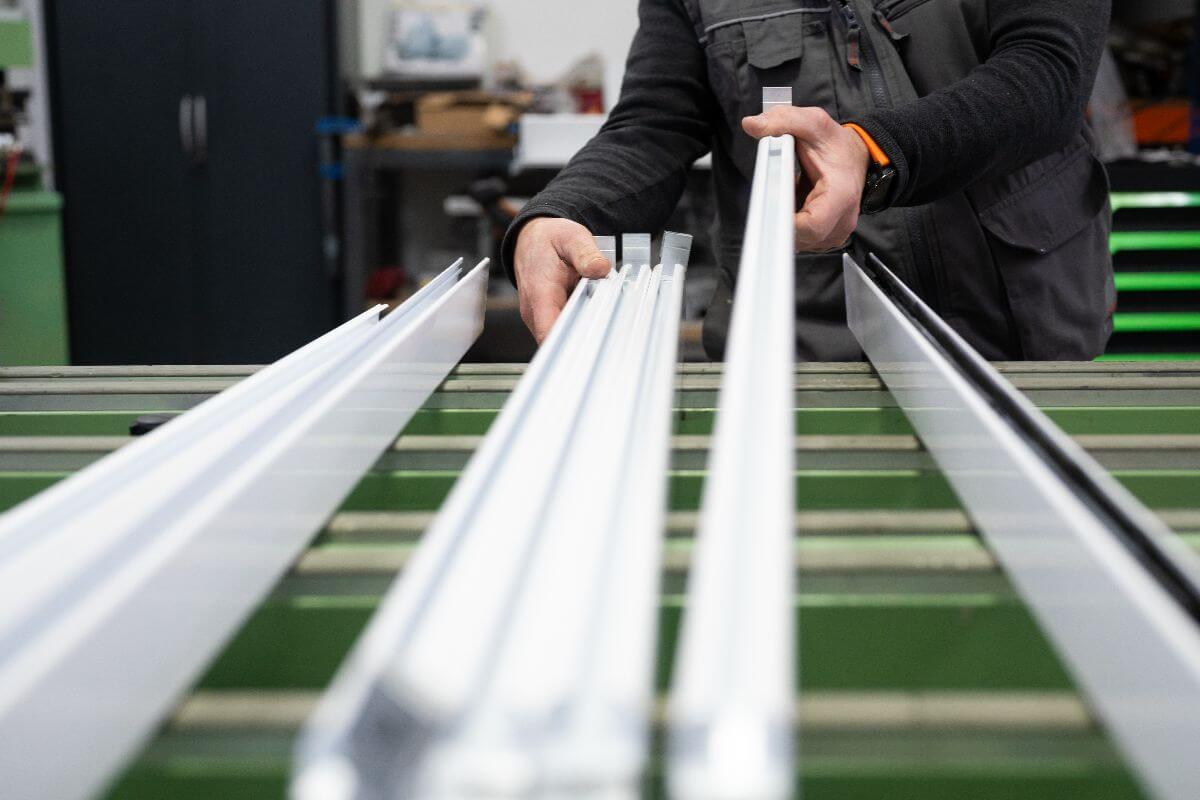

Profile Design and Shape

Profile geometry influences both performance and fabrication efficiency. Simple, symmetrical shapes with uniform wall thickness extrude more evenly, minimizing weak points and production challenges. In contrast, sharp corners or deep cavities can concentrate stress and complicate tooling.

Standard shapes such as channels, rectangular tubes, and angles provide predictable strength and are easier to manufacture. Custom designs can be developed for specific architectural requirements, though production may take longer. Maintaining consistent wall thickness supports structural integrity and quality.

Well-planned geometry ensures smoother project execution and reliable performance. When profiles integrate seamlessly with gaskets and glazing, on-site installation becomes more efficient and precise.

Thickness and Structural Strength

Wall thickness determines a profile’s stiffness and load capacity, so selecting the right measurement should match project loads and building codes. Thicker sections increase strength but also weight and cost, while thinner ones need careful evaluation to avoid weak points.

Tight tolerances and uniform thickness improve fitting with frames, gaskets, and glazing systems, reducing installation errors and streamlining assembly. Balancing these factors ensures structural reliability, cost efficiency, and long-term performance.

Surface Finish Options

Surface finish influences both appearance and durability, so you’ll want to select finishes that suit your installation environment. For instance,

- Anodizing provides corrosion resistance and a uniform metallic look.

- Powder coating offers color variety and UV protection.

- Natural mill finish maintains a raw look but needs more upkeep.

Environmental conditions such as coastal air, strong sunlight, and high-traffic exposure influence the most suitable finish for your project. The right choice protects the aluminum and preserves its appearance over time.

Evaluating finish together with alloy and geometry ensures lasting performance and visual appeal. Thoughtful selection also minimizes maintenance needs and long-term costs, keeping your installation in excellent condition for years.

Long-Term Performance and Durability

Long-term performance relies on how alloy, shape, thickness, and finish work together in your specific conditions. Selecting compatible combinations helps reduce maintenance, preserve appearance, and ensure your profiles perform reliably over time. Checking material certifications and temper data can also minimize risk.

Batch consistency, inspections, and finish compliance help guarantee that your profiles meet design specifications. This attention to quality reduces potential issues on-site and keeps your project on track. Consistent quality control protects both your schedule and your investment.

When your specifications match environmental demands, your aluminum profiles will require less upkeep and maintain both function and aesthetics, ensuring your installations last for years.

Why the Right Aluminum Profiles Prevent Costly Installation Mistakes

Selecting the right alloy, profile, and finish prevents issues such as corrosion, warping, misalignment, and weak joints. When materials are suited to the project and environment, the installation performs reliably.

Avoiding overly complex shapes also minimizes fabrication defects and delays. Profiles designed with manufacturability in mind help keep production smooth and cost-efficient.

Finally, ensuring compatibility with other building materials and systems prevents installation problems. This alignment between design and fabrication saves time and resources while ensuring the final structure meets both functional and aesthetic goals.

Explore Customizable Solutions with AMC Aluminum

At AMC Aluminum, we offer standard and customizable architectural profiles tailored to your project requirements. You can adjust shapes, dimensions, alloys, and finishes to achieve both functional and aesthetic goals.

Our design support ensures accurate specifications, helping you minimize fabrication errors and installation challenges. With flexible solutions that integrate seamlessly with other materials, you can achieve smooth installation and high-quality, reliable results.

Key Takeaway

With a more thorough understanding of the things to consider when choosing aluminum profiles for architectural use, you can achieve a build that is both visually appealing and structurally sound, ensuring durability and long-term performance.

Choose the right aluminum profiles for your next architectural project with AMC Aluminum. We offer durable, versatile solutions that meet both structural and aesthetic requirements. Contact us today to learn more and get expert guidance for your build.

.jpg)

.jpg)

.jpg)