What are the aluminum profile quality standards every builder should know?

- Alloy composition and strength

- Dimensional accuracy

- Surface finish quality

- Corrosion and weather resistance

- Thermal and energy performance

- Compliance with global and local standards

Overview

- Aluminum profiles significantly impact building strength, aesthetics, and efficiency.

- In the Philippines’ humid and rainy climate, meeting quality standards—such as alloy strength, dimensional accuracy, surface finish, and weather resistance—is vital.

- AMC Aluminum delivers ISO-grade profiles that ensure durability, energy efficiency, and long-term performance while reducing maintenance and installation issues.

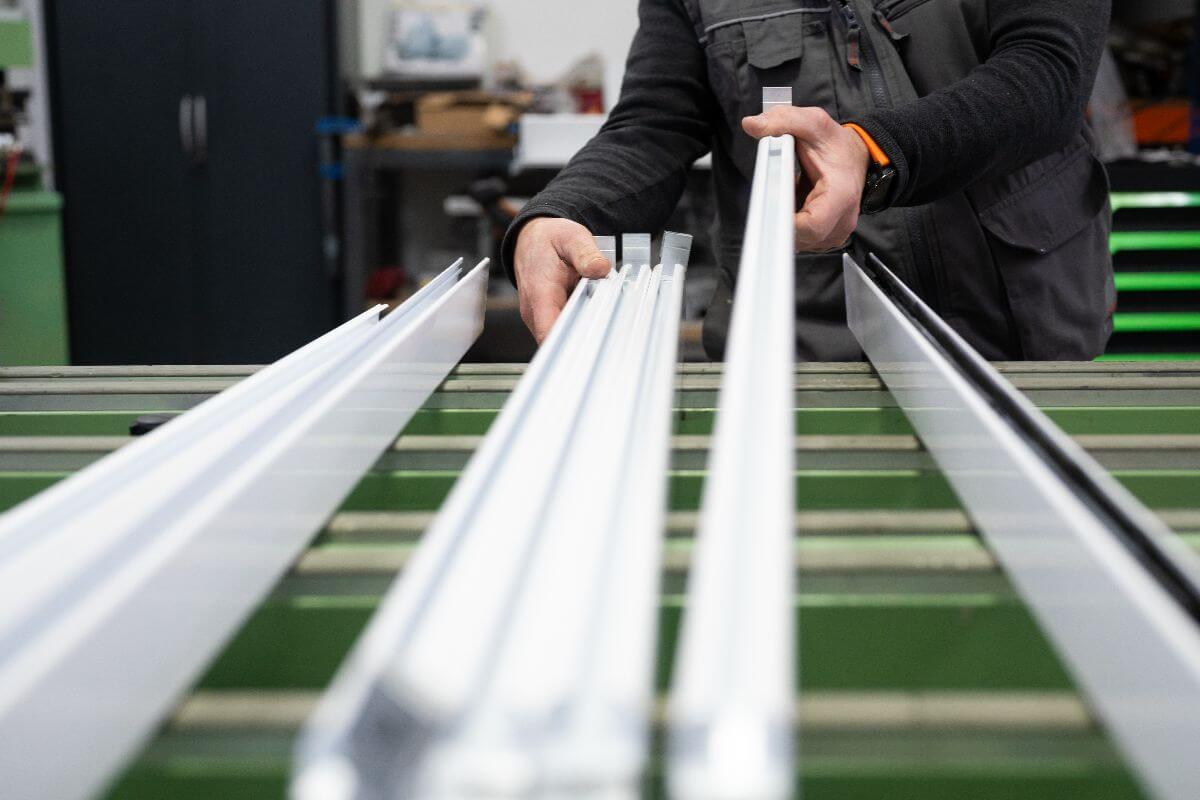

Aluminum profiles do more than frame windows and doors as they contribute to a building’s overall performance and efficiency. Following aluminum profile quality standards ensures proper insulation and prevents air or water leakage.

In the Philippines’ hot, humid, and rainy climate, compliant aluminum profiles help regulate indoor temperatures, lower energy costs, and prevent moisture damage. AMC Aluminum offers durable, precise, and stylish profiles that builders can rely on for lasting performance and reliable results across any project.

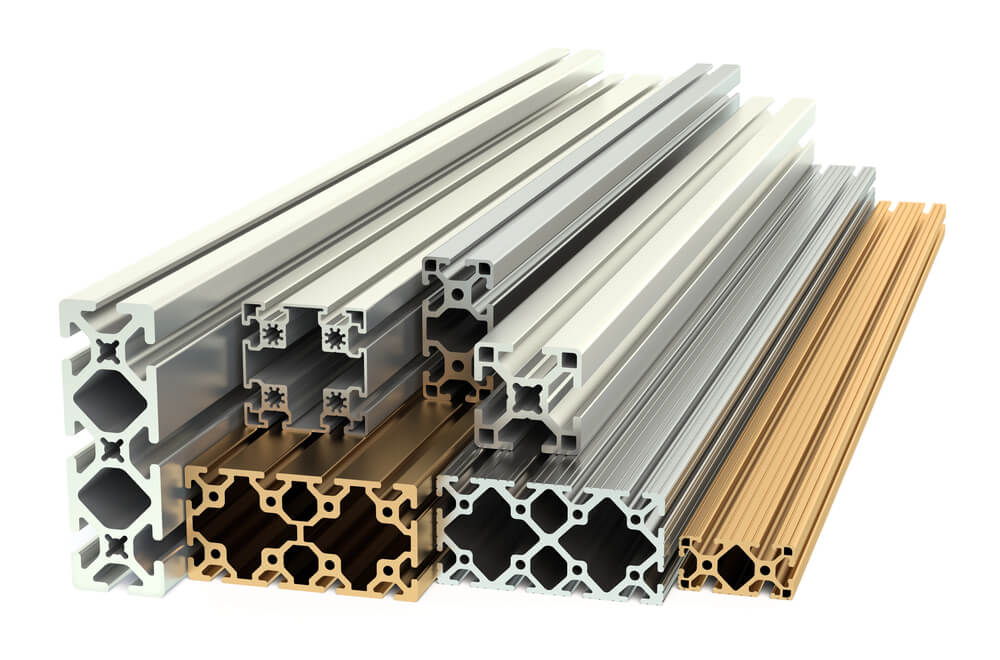

Alloy Composition and Strength

Aluminum profiles are made from specific alloys, most commonly 6061 and 6063, and selecting the right one is crucial for safety and performance.

- 6061 Alloy: Stronger and more rigid, ideal for load-bearing applications such as structural frames, railings, or outdoor supports. It resists bending and maintains long-term stability.

- 6063 Alloy: Slightly softer and more flexible, making it easier to extrude and shape for windows, doors, curtain walls, and decorative trims. It offers smooth finishes with good durability and corrosion resistance.

Choosing the correct alloy ensures that each profile meets its intended function, whether for strength, flexibility, or aesthetic requirements, and avoids issues like warping, installation difficulties, or premature wear.

At AMC Aluminum, we manufacture our profiles from ISO-grade billets using advanced machinery from Taiwan. This ensures that each alloy meets the strength, rigidity, and durability requirements for both residential and commercial applications.

Dimensional Accuracy

Dimensional accuracy ensures that aluminum profiles are consistent in thickness, width, and straightness. Even minor deviations can create gaps or looseness when profiles are installed, which may lead to water or air leakage, compromised insulation, and weakened structural connections.

For example, a slightly oversized or undersized window frame can become loose, reducing stability and potentially causing long-term damage to the surrounding structure. Accurate profiles fit precisely, maintaining structural integrity, proper sealing, and durability.

Builders who prioritize dimensional accuracy minimize installation issues, avoid costly repairs, and ensure that every component performs as intended over the life of the building.

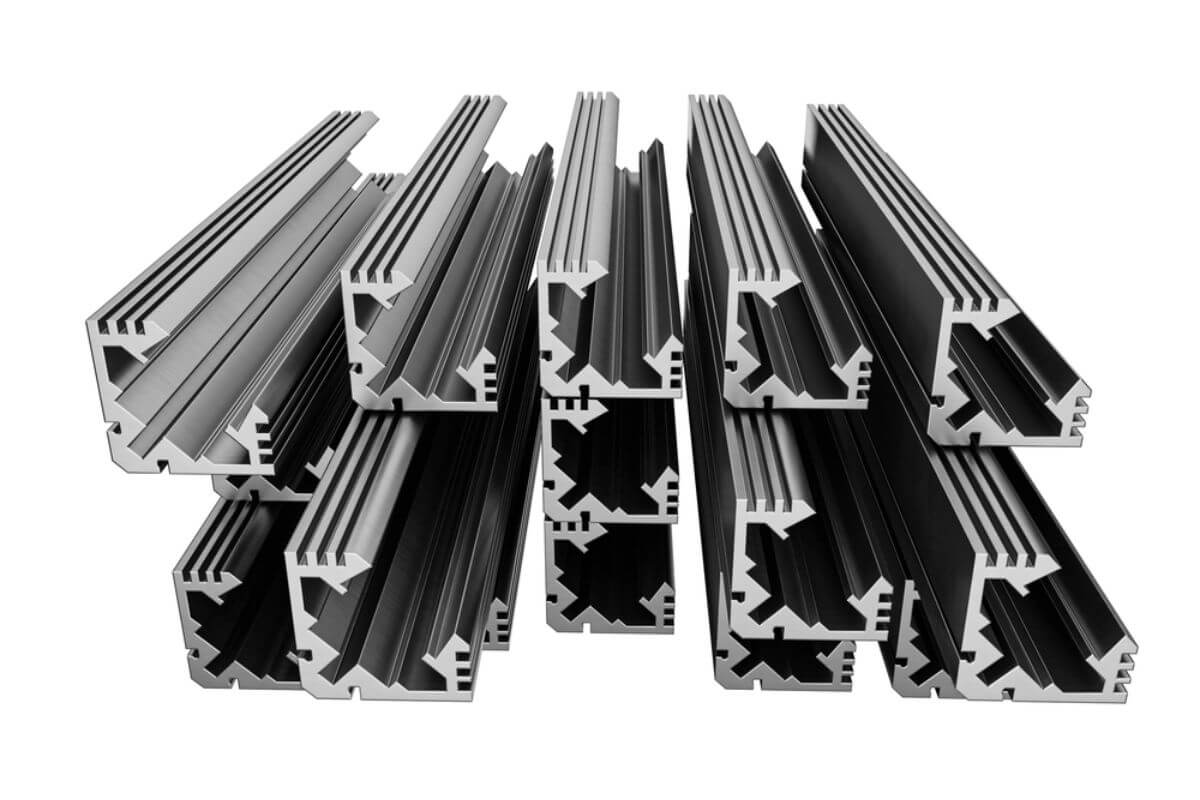

Surface Finish Quality

The surface finish of aluminum profiles affects appearance, texture, and long-term resistance to minor wear. A high-quality finish, such as anodized or powder-coated, prevents scratches and maintains a smooth, professional look even in high-traffic areas.

Poor finishes don’t just look bad, but they can also make cleaning and maintenance harder and reduce the profile’s aesthetic appeal in visible applications like office partitions, window trims, or decorative facades.

Unlike corrosion resistance, which protects the metal from environmental damage, surface finish focuses on visual integrity and everyday usability, ensuring structures look polished and professional for years.

Through our powder coating services and precision profiling, our aluminum products maintain their strength and finish over time. This ensures that every project is resilient, low-maintenance, and long-lasting, giving builders confidence that their structures can withstand harsh environmental conditions.

Corrosion and Weather Resistance

This standard ensures profiles can endure extreme environmental conditions, such as coastal salt air, heavy rainfall, or humidity, which are a frequent cycle in the Philippines.

While surface finish protects against minor scratches and wear, corrosion and weather resistance determine structural longevity under real environmental stress.

For example, window frames near the coast without proper corrosion resistance may weaken or develop rust internally, leading to compromised load-bearing capacity or water leakage. Prioritizing this standard safeguards structural safety, not just appearance.

Thermal and Energy Performance

Thermal performance addresses the insulation and energy efficiency of a building. Aluminum frames with poor thermal design can allow heat or cold to pass through, increasing energy consumption and creating uncomfortable indoor climates.

Choosing profiles with proper thermal barriers or energy-efficient designs helps reduce electricity bills and improve occupant comfort, especially for large glass facades or commercial buildings.

Compliance With Global and Local Standards

Aluminum profiles that meet ISO, ASTM, EN, or Philippine National Standards (PNS) have been tested for strength, durability, and safety. In the Philippines, using non-compliant profiles can create serious problems during inspections, especially in high-risk areas prone to typhoons or heavy rains.

Compliance ensures that profiles withstand expected loads, environmental conditions, and safety requirements, protecting both builders and occupants. It also signals professionalism to clients and authorities, demonstrating that your construction follows regulated practices.

Neglecting this standard may lead to legal complications, higher maintenance costs, or safety hazards, making it a non-negotiable aspect of quality construction.

Key Takeaway

By knowing what to look for when it comes to aluminum profile quality standards, you can ensure they combine strength, precision, and durability, preventing hidden issues like structural weakness, leaks, or premature wear.

Ready to secure high-quality aluminum profiles for your next project? Explore our solutions or contact us at AMC Aluminum for expert guidance and personalized recommendations.

.jpg)

.jpg)

.jpg)