What are the types of aluminum channels?

- U-channel

- C-channel

- J-channel

- Hat channel

- T-slot channel

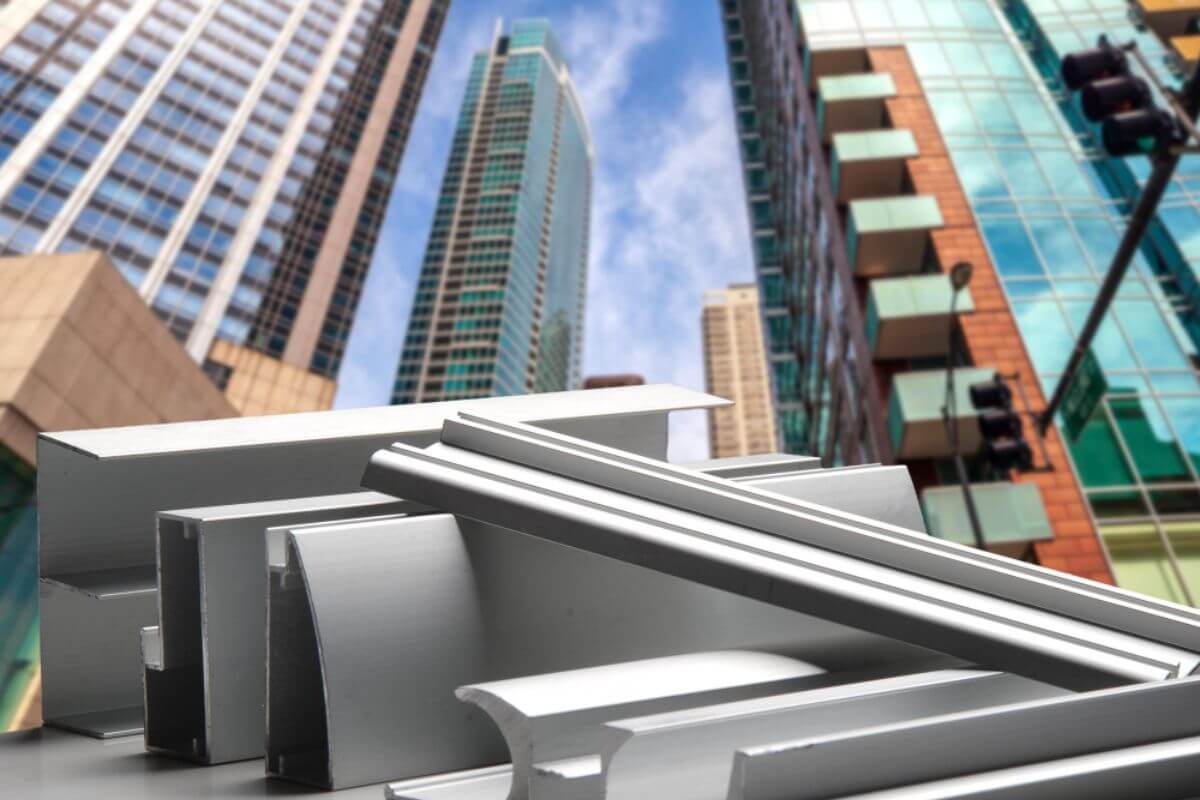

When it comes to construction and industrial projects, aluminum channels are a versatile and reliable solution. They provide a sturdy base for framing and can be used in a wide variety of applications, from framing windows and doors to building support structures for ceilings and floors. There are several different types of aluminum channels available, each with its own unique properties and benefits. In this post, we’ll take a look at five of the most common types of aluminum channels and how they can be used in construction and industrial settings.

What is an aluminum channel?

An aluminum channel is a U-shaped metal extrusion made of aluminum that resembles the shape of the letter “U.” It is commonly used in construction, manufacturing, and other industries for a wide range of applications, such as framing, support, reinforcement, and decorative purposes.

Aluminum channels are available in different sizes, shapes, and thicknesses to accommodate various requirements and specifications. They can be used alone or in conjunction with other materials to create complex structures and designs. The versatility, durability, and lightweight nature of aluminum make it an ideal material for the production of channels and other extrusions.

U-channel

U-channels are one of the most commonly used types of aluminum channels and for good reason. Their simple design consists of a “U” shape with two legs that are parallel and perpendicular to the base. This makes them easy to use in a wide variety of applications, including framing, edging, and support.

U-channels are often used in construction projects to support windows, doors, and glass panels, as well as in manufacturing settings to support machinery and equipment.

C-channel

Similar to U-channels, C-channels have a simple design consisting of a “C” shape with one leg longer than the other. This gives them a flatter profile, making them ideal for applications where a low profile is required.

C-channels are often used as frames for mirrors, as well as in industrial settings for mounting lighting fixtures and other equipment.

J-channel

J-channels are a type of aluminum channel that has a unique “J” shape, with one leg perpendicular to the base and the other leg angled at 45 degrees. This makes them ideal for applications where a secure hold is required, such as mounting siding or roofing materials.

J channels are also commonly used in window and door installations to secure and support the edges of glass panels.

Hat channel

Hat channels, also known as furring channels, have a unique design that resembles a hat, with two legs that are parallel to each other and perpendicular to the base. This makes them ideal for applications where support is needed over a long span, such as in ceilings or floors.

Hat channels are often used to support drywall and other finishing materials, as well as in industrial settings to support piping and wiring.

T-slot channel

T-slot channels are a type of aluminum channel that has a unique “T” shape, with a groove on the top that allows for easy insertion and removal of accessories and attachments. This makes them ideal for applications where customization and flexibility are required, such as in manufacturing and industrial settings.

T-slot channels are often used to build custom workstations, conveyor systems, and other specialized equipment.

Are Aluminum Channels Used in the Construction of Aluminum Windows?

Yes, they are. You can find them in our aluminum windows here on AMC Aluminum. They are used for the construction of this window for several reasons.

Structural Support

Aluminum channels provide structural support to the window frames, which are important in ensuring the stability and longevity of the window. The traditional U-shaped design of the channel adds rigidity and strength to the frame, helping it to withstand external forces such as wind and impact.

Made of Lightweight Material

Another advantage of using aluminum channels in aluminum windows is their lightweight nature, which makes them easy to handle and install. This characteristic is especially crucial when constructing large windows or multiple windows, where the weight of the materials used can become a significant concern.

Resistant to Corrosion and Rust

Thirdly, aluminum is a durable material that is resistant to corrosion and rust. This makes it an ideal material for use in windows, as it can withstand exposure to the elements without deteriorating over time.

Customizable

Finally, aluminum channels can be easily customized to meet specific design requirements. They can be cut to the desired length and shape, and can also be powder-coated or anodized to achieve different colors and finishes.

Key Takeaway

Aluminum channels are an essential component of many construction and industrial projects. With a variety of types and designs available, there is an aluminum channel that is perfect for every application. Whether you need to support a window, build a support structure, or mount specialized equipment, aluminum channels are a reliable and versatile solution that can meet your needs.

Here at AMC Aluminum, you can expect to find aluminum channels on our various aluminum profiles. We provide customers with only some of the most high-quality aluminum windows in the Philippines. Contact us today for any inquiries.

.jpg)

.jpg)

.jpg)