What is the difference between copper vs aluminum conductors?

- Conductivity

- Physical attributes

- Connectors

- Pricing

- Application

Considering what metals to use for your construction and electrical jobs? When it comes to conductor materials, there are really only two to consider: copper and aluminum. They are the most used metals for this application, but what sets them apart?

Aside from being conductive, they don’t share many other characteristics — meaning they have plenty of unique strengths and weaknesses. If you want to learn more about the differences between copper vs aluminum conductors, read on! Some of these factors may help you choose the right metal for your job.

What is electrical conductivity?

Conductivity is one of the basic properties of any material, and electrical conductivity is a specific aspect of that. Electrical conductivity measures the amount of electrical current that can pass or be carried through a material.

Conductors are devices made from materials or substances that allow an electrical current to move easily through them. Certain metals are used in this application because they allow electrons to flow smoothly between their atoms — and copper and aluminum are two of the most electrically conductive metals.

Conductivity

Except for silver, copper is the most electrically conductive metal — so much so that it has become the international standard for this application. The International Annealed Copper Standard (IACS) was developed in 1913 and is used to equate other metals’ electrical conductivity with that of copper. However, it’s important to note that pure copper is highly conductive, and the addition of impurities or the use of certain copper alloys will adversely affect its conductivity.

Aluminum, while not being as conductive as copper, is still known for its high electrical conductivity. When looking at volume, the conductivity of pure aluminum is around 60% of pure copper. But, when looking at weight, one pound of aluminum has the same capacity as two pounds of copper. So, despite being less conductive in general, it can still be more efficient in certain applications by weight.

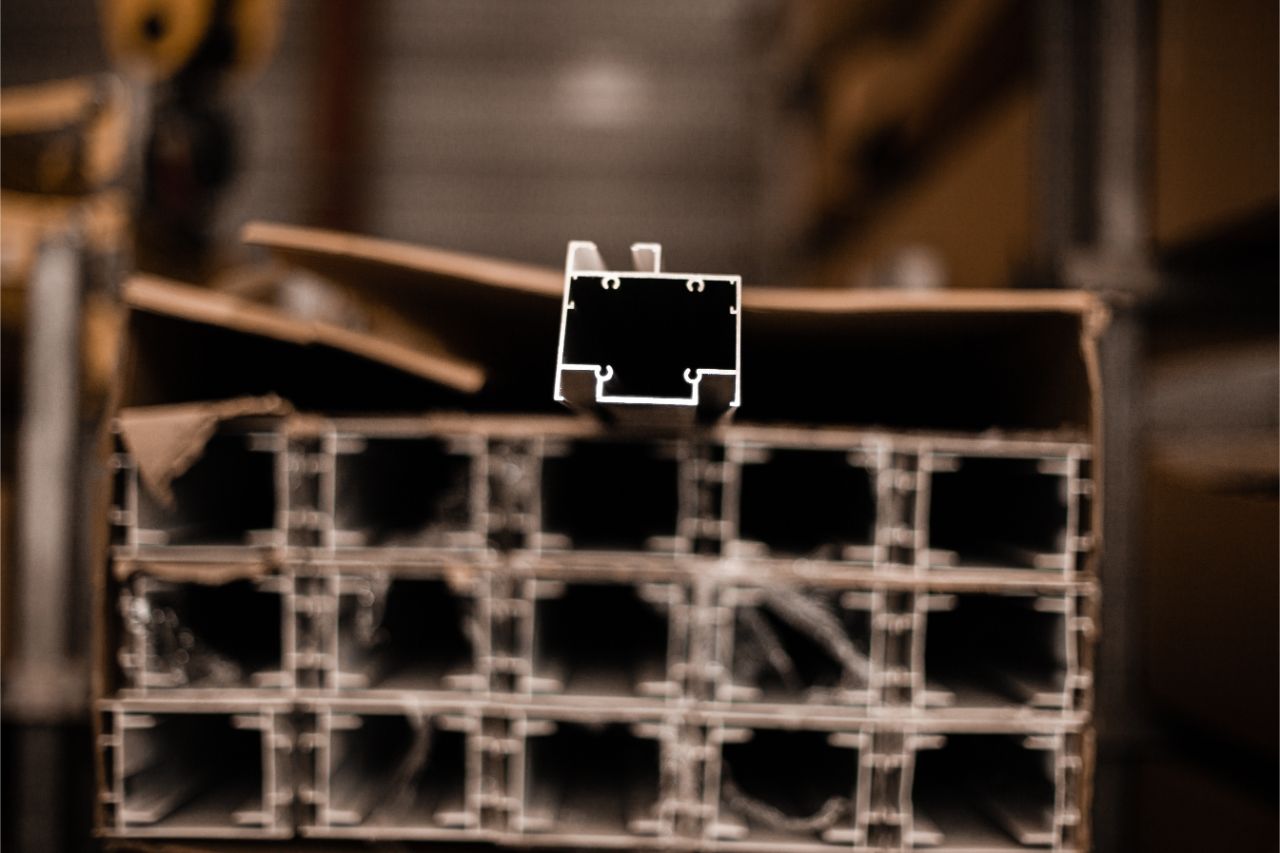

Physical attributes

Copper is not only an excellent conductor of electricity but is very malleable and ductile, which means it can be formed into multiple shapes. It can be beaten into sheets or pulled into a wire. Copper also has high tensile strength and withstands heat well. Due to this resistance, it also conducts heat well and does not easily expand or contract as much as other metals when exposed to varying temperatures. When pure copper is annealed, it gains the capacity to conduct 100% of the electrons that flow through it.

Aluminum has good tensile strength and mechanical properties, both of which can be easily improved through cold working and alloying. Aluminum is also easy to work with, as it is lightweight, flexible, and malleable. This attribute allows for faster installations and repairs. Aluminum is also great in colder temperatures and does not become brittle nor lose its ductility. Lastly, while copper may have greater tensile strength, it is worth noting that aluminum conductors tend to be lighter overall, so they don’t necessarily need the same level of tensile strength.

Connectors

Connectors are responsible for joining conductors to a whole electrical system. They are responsible for carrying the electric current between wires, cables, and other electrical equipment made from copper and aluminum. They are fundamentally important to the network’s efficiency.

When choosing between copper vs aluminum conductors, connectors also play a role in that decision. This is because if the connectors are not the right type for the metal, or are incorrectly installed, then it can cause an electrical failure or hazard.

With aluminum, the connectors must be rated for use for that specific aluminum grade or alloy. Connections rated for use with aluminum are frequently also able to be used with copper and are marked as such. One example is the AL7CU, a connector suitable for use with copper or aluminum conductors at 75°C. Furthermore, in cases where these connectors need to be soldered, copper conductors are better to use, as aluminum tends to be difficult to solder.

Pricing

Aluminum conductors, being considerably lighter, always cost less than copper conductors. This lower price point is also aided by the fact that aluminum is highly recyclable. While copper is also often recycled, most aluminum products nowadays are actually secondary aluminum. Furthermore, the market pricing for aluminum is much more stable than that of copper. As a result, it’s not uncommon for aluminum to be one of the cheaper metals on the market — aluminum wiring can cost just half the price of copper wiring.

For a residential home, using aluminum conductors instead of copper conductors can save builders thousands. For commercial buildings and industrial applications, the cost-savings can even reach millions.

Application

Copper is typically used to create conductors for buildings. Nearly all electronic cables in commercial, industrial, and substation buildings are made from copper, due to their high conductivity. Copper conductors are commonly found in power generation, power distribution, telecommunications, and automotive electronics. On a smaller scale, some electronics and appliances also use copper components in the form of soft wire.

On the other hand, aluminum is used in applications where weight and cost savings are critical. In technology like satellites, and vehicles like aircraft, and some commercial automobiles, its low-weight properties are used to avoid additional friction and drag. Aluminum conductors are also used in long-distance power lines, power cables, power connectors, and circuit breakers. Depending on the building and application, it can even replace copper wiring.

Key Takeaway

When it comes to choosing conductors, considering the many differences and advantages between copper vs aluminum is important before making a final decision. AMC Aluminum knows that choosing the right material for the job can make all the difference, which is why we offer our help to those considering aluminum for their projects. Our expertise in aluminum manufacturing and profiles enables us to answer any questions you have, and help you make the right decision.

Want to work with AMC Aluminum on your next project? Send us a message here, and our team will be in touch.

.jpg)

.jpg)

.jpg)